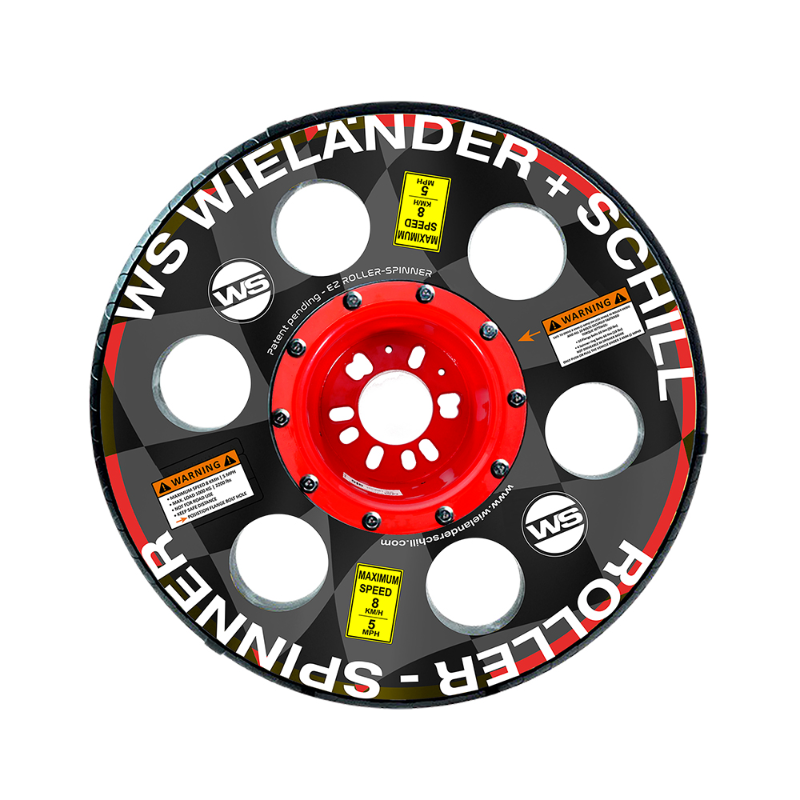

WS Roller-Spinner with 5/6 rim bolt circle

Robust universal wheel for cars and High Voltage vehicles - 2 solutions in one wheel.

The innovative mobility solution on any terrain, including uneven asphalt, gravel, grass or dirt. Can be driven into most paint booths. The WS Roller-Spinner is available in two versions for 4/5 and 5/6* rim bolt circle. Suitable for AWD, FWD, RWD, and high-voltage vehicles.

The mounting system is a 60º taper fit that allows most OEM bolts and nuts to be installed without spacers or washers. The hub easily bolts to the vehicle hub in less than a minute.

*Fits 98% of all 6-eyelet screw patterns, but only partially fits 5 eyelet screw patterns. (5x120-5x130)

WS Roller-Spinner with 5/6 rim bolt circle

The WS Roller-Spinner is superior to a steel universal wheel because it is cast in one piece. Other steel universal wheels have a separate tire that is glued on. When overused, the tyre can come loose and fall apart. Also, the WS Roller-Spinner weighs 40% less than a steel wheel, making it much easier to handle. The sturdy 10mm steel core and universal 4/5 or 5/6 rim hole circle pattern are also suitable for high-impact wrenches and prevent over-spinning.

Replaces painting wheel

Painting wheels are becoming more and more established in paint stores and are increasingly prescribed as a safeguard for customers and insurance companies. However, they pose major challenges in terms of warehousing, logistics, and handling, especially for smaller companies. The WS Roller-Spinner provides a remedy due to its properties, solves the problem of storage and logistics, and thus reduces the costs incurred by the company.

Spare wheel function

The WS Roller-Spinner can be used as a universal spare wheel. This avoids blocked lifts and workstations, which in turn avoids lost sales.

With a maximum speed of 8 km/h, a vehicle can be moved around the workshop site with the WS Roller-Spinner, ensuring flexible and efficient work processes.

Supplement for maneuvering assistance

The WS Roller-Spinner enables the pushing or pulling of unloaded electric vehicles, vehicles with blocked brake systems, or parked vehicles. It is an ideal supplement for classic maneuvering aids, as these work only to a limited extent on uneven surfaces such as pavement or gravel. Due to the rotating inner ring, it is particularly suitable for recovering electric vehicles or vehicles with automatic transmissions, as the gear cannot be set to neutral mode on these vehicles in the OFF state.

Mounting - fast and safe

1. Remove existing wheel bolts or nuts - use the assigned jacking points in the vehicle owner's manual to safely lift the vehicle. Use a jack or lift to remove the OEM bolts or nuts and remove the wheel from the vehicle.

2. Align the WS Roller Spinner to the vehicle hub - a hub ring can be used for easier alignment. Use the correct ring size and insert it into the center hole before aligning.

3. Attach the bolts or nuts - wheel bolts or nuts vary by manufacturer; always check that the length of the bolts is correct.

4. Tighten the bolts or nuts - when the WS Roller Spinner is in the correct position and flush with the hub, tighten the bolts or nuts to a torque of 65 N/m. Manually check the rotation to make sure the wheel moves freely and there is no play.