This item contains the following components:

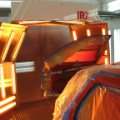

Infrared arch IRT PowerCure shortens curing times for all paint materials

High profitability in a car refinishing paint shop is obtained by processing repair jobs in the most efficient way.

Bottlenecks and waiting times must be minimized so the car can be returned to its owner in the shortest possible time.

The infrared arch IRT PowerCure is designed to be installed inside the spray booth and along with the SETS features, we take in-booth drying to the next level.

Details about SETS features – IRT PowerCure Saves:

Energy

Why heat the whole spray booth and the whole car when most drying jobs comprises of 1-2 panels of the car?

The IRT PowerCure will only heat and cure the selected panels of the car. The computer keeps track of position and status of the IRT PowerCure and will turn on- and off the individual lamps in a fraction of a second, in order to only use the energy needed for the curing job. This radically reduces the energy consumption and pays off the investment in a very short time.

Time

When the painter has completed the finishing job and exits the spray booth he makes a short stop in front of the touch screen. This is where selections of panels to be dried and paint type are done quickly and easily. It is as easy as using your personal smartphone. A typical damage is cured in 10 minutes or less. Leave the car for another 10 minutes to cool down.

It can then be removed from the spray booth, polished and processed further. Hence the IRT PowerCure offers you increased drying capacity as it turns your traditional booth into a rapid curing booth.

Space

Space is often precious in a car refinishing paint shop. Traditionally two or more spray booths have been installed when more drying capacity was needed. This blocks and reduces the available space for other important parts of the shop such as the preparation bays. The IRT PowerCure gives you increased drying capacity by turning your traditional booth into a rapid curing booth and typically this gives you enough drying and spraying capacity without investing in a second or third booth. IRT PowerCure cures the paint from the inside and out without retaining solvents and moisture. This is why the car can be polished and processed further immediately after cool down.

The result

You save space and improve the throughput of cars in your bodyshop.

Facts |

|

Technical Data |

|

| Voltage | 400 V, 3 Ph/PE |

| Frequency | 50-60 Hz |

| Installed power | 54 kW |

| Used power preset from factory | 43 kW (max.) |